SC Media in Bulgaria - Learning about What makes Coda Audio Special

March 2025 – On November 11th and 12th 2024, a group of SC Media employees were lucky enough to get to travel to Sofia, Bulgaria to see Coda Audio’s manufacturing process. We did not know what to expect from the country as well as the time with our manufacturer, but we were excited for the process. What we saw exceeded our expectations and made us feel really good about our decision to partner with this company.

For this post, I wanted to do things a bit differently. Instead of offering a similar case study structure, I thought it made sense for me, Noah Daoust, to offer a first-person account of our experience at Coda Audio in Sofia, Bulgaria.

Our first tour occurred at the ‘New’ factory. A beautiful building, we were pleased to be greeted by Coda’s owner, Svetly Alexandrov, who was kind enough to be the one conducting the tour. Not a lot of companies have their founder and CEO giving factory tours.

The tour began with us being shown raw materials, an unimpressive collection of steel. Svetly tells us that we will see the step-by-step process of how Coda is able to go from a piece of steel (pictured in Svetly’s left hand) to a finished product (similar to the finished component in his right hand). Our team has been on many factory tours, so we nodded politely. We didn’t realize to what degree of manufacturing we were about to witness.

Yes, machines are critical for Coda to manufacture product, but many hands touch every single Coda speaker along the manufacturing process. For example, we got to see a Coda employee assemble a new HOPS10 loudspeaker (video on the left). There are various glues, screws and hammering involved to get the cabinet to be solid. These speakers are tough!

It is amazing to see how many processes are still very human. For example, we got a great clip (right) of the extensive sanding process done to a G Series Subwoofer, that is done both by machine as well as person.

We loved observing the painting process at Coda. Of course, black is the standard colour, but thanks to the Canadian market Coda Audio has created a cost effective way to paint speakers in any RAL colour with no minimum quantity. This allows us to create incredibly sounding product that adheres to colour obligations of certain installations.

It was amazing that we were able to get so close to the painting process at Coda. Svetly tells us that if we were doing it 8 hours a day, a suit like the one in the video would be necesarry, however he invested a large sum of money into HVAC considerations for this space, so one could get so close and breathe comfortably.

.

Coda manufactures everything. Every part of the speaker comes from Coda, and one of these key pieces is the rigging pins. Svetly told us a great story about how he brought in 4 different manufacturers of pins for stacking speakers, and none of these potential partners could do what he requested. Each had different specific reasons that didn’t agree with his desired functionality. He said he threw his hands up in the air and said, fine, I will have to build them myself. It is a small piece of the picture, but what this is indicative of is how much Svetly takes ownership of his company. There is no compromising – in components, in electronics, in cost, etc. Coda is dead set on making the best product money can buy, and it will be engineered to a level that is industry leading.

Another word that comes to mind after spending time with Svetly is artisan. Svetly knows that Coda is not the biggest manufacturer in AV, and he does not care. What he is passionate about is that he is in control of every process in building his products.

One is always curious how a company judges themselves. Every company is different and has different goals. Some want to sell the most product, make the most money, enjoy the largest percentage of market share, etc. So, I had to ask him, what makes Coda the best in the business in your view?

His answer was encouraging as a distributor. For him, a lot of Pro Audio is subjective. Certain things like tonality are subjective, and differ from person to person. But there are many things that are objective, such as weight, transducer efficiency, phase linearity, etc. And for him, Coda has solutions that simply put outperform competitive solutions on the market. He is not afraid of any other company or product, and would gladly take them on in an A-B demo.

Our tour continued in the Electronics department, which is situated above all of the speaker manufacturing. A much quieter space, we see many Coda employees building small components from scratch. We also were able to see what Coda is calling the PAD4, which is going to be the building block of LINUS6.4i and amplifier platforms to come. You can see the module in the picture on the right.

They were testing a new batch of units when we visited, units that would go into our first order of LINUS 6.4i amplifiers, which everyone from the SC Media team was thrilled about!

Amplifiers go through a rigorous testing process to be approved. While we were there, we visited their burn-in room where amplifiers had been running 24hrs+.

Electronics is home to a lot of innovative and tedious processes as well. On the left we can see inductors that form part of the passive crossover network in all Coda speakers being wound and measured to spec. It’s a small thing, and a small process, that may be cheaper to just buy as is. But it shows how every part of the process is controlled. Control is a key part of the Coda difference.

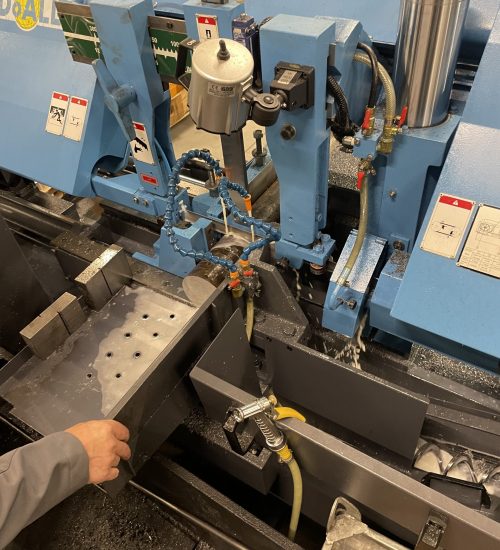

We broke for lunch, and then made our way to the second factory. It is referred to as the ‘old’ factory, but here a ton of key processes occur for loudspeaker component manufacturing. It should be known as the first factory, and coincides directly with Coda’s growth as a Professional Audio manufacturer.

They have owned this building for many years, and while it is currently under renovation, we spent the afternoon climbing down the 4-story building, examining each station of the factory, where the word meticulous is the one that comes to mind. Many different components are built here, in an incredibly involved fashion.

Take voice coils for instance. This clip (left) is of Svetly talking about how the glue on the voice coils is measured to milligram. This is the level of control they have over the manufacturing process.

And listen to Svetly here (right) explain how voice coils are laminated together. It requires great precision and dexterity, but again this is work that is done by people using machines, not just machines.

This is an example of processes that occur of every component of the speaker. Whether it be electronics, transducers, woofers, etc. Everything is manufactured to the nth degree.

Over the course of the day, we thought to ourselves, why two factories? As the owner of both, wouldn’t it make sense to consolidate both efforts and bring all the workers to the new factory? They certainly have the real estate to expand.

Svetly told us that he had considered it, but ultimately decided against it. Coda boasts a great retention level, with the majority of the employees working there for a long time. While it would be better for the business, Svetly felt as though these people, who helped him build Coda, had built their lives around their work. He didn’t want to cause unnecessary strain on his employees. So each factory operates in separate facilities on different sides of Sofia, but the staff in the older factory continues to be happy and loyal to their leader who puts their quality of life first.

As we are a Coda distributor, this may read as a one-sided view of a manufacturer. I do not want people to come away with this thinking Coda is perfect, because no company or person is. What I do think is the biggest takeaway is the level of expertise used to build these products is unbelievable. We were blown away, and while we are sold on the advantages of working with Coda Audio, we thought it was important to show pictures, videos, and first-hand accounts of our experience because we feel reinvigorated to go out in our territories and push the brand.

For those who are current believers in the brand, this will make you want to push harder too. If you have never dealt with Coda before, we hope that this article piques your curiosity. Once you try it, you will feel how we do. After all, hearing is believing.